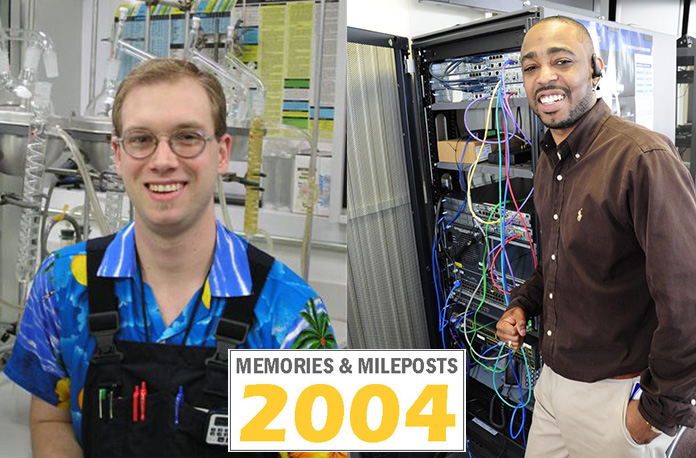

2004: A Tale of Two Joes — Joey Selby and Joseph Cody

The year was 2004, and two not-so-average Joes joined Alyeska.

Joey Selby started as a lab technician in Valdez on Jan. 5, while Joseph Cody began his job as an IT analyst in Anchorage on April 12. They were starter jobs as individual contributors in a dynamic workplace and neither could have known that they would be promoted up through increasingly interesting opportunities to eventually each hold significant leadership roles on TAPS.

Today, Joey is the manager of the Operations Control Center; Joseph is the Business Architect Manager for IT. They’ve each had their share of experiences, challenges, and reflections during their time on TAPS. They sat down with Alyeska’s Corporate Communications team recently to talk about their careers so far.

Tell us about when you first joined Alyeska.

Joey: I started with Alyeska in 2004 and I was so thrilled to get the job. I don’t know how Joseph recalls it, but it was tight times for Alyeska in 2004, there was a kind of a hiring freeze around that time. I had been working as a contractor and I’d spent six months in the lab in Valdez. I’d fallen in love with my teammates. I didn’t want to go anywhere – I felt completely at home! So going from being a contractor to an employee, I was ecstatic. That lab technician job was kind of my first real job after graduating from college. There was stiff competition for the position and when I got it, the whole family celebrated… for months!

Joseph: It pretty much was my first serious job out of college. I was doing three different jobs at the time, trying to stack up money, because I’d just gotten out of college. I came in through the Building Foundations for Excellence program. And similar to Joey, there was a lot of competition. The head of the BFEP program was (now Alyeska Vice President/CFO) Lisa Booth. It’s kind of ironic, we’ve all come full circle. I came in through that, stayed for about two years, and eventually it became official in 2004 and that’s when I became permanent. Similar to Joey, I was ecstatic. The pay increase! This was my first real job, a career, not something I just did to clock in and clock out. I felt like I’d fully arrived at that point.

What were your early impressions of Alyeska and TAPS?

Joey: It’s very easy to see the VMT as just the last dot on the pipeline map. As I became an Alyeska employee and started taking more time to explore all the operating areas on Terminal, it was just like drinking from a fire hose, I was amazed to see how much work goes into operating and maintaining the system. Every day you’d look under a rock and find a whole team of people doing something you never imagined before. I spent the first year with my eyes popping out of my head. Not to mention that I had never worked in a lab before. I just happened to have the chemistry credits required, and be in the right place, at the right time. The only reason I survived was because the lab technicians selflessly took me under their wing and made me one of their own.

Joseph: There was a lot of nervousness and anxiousness. You had this expectation, I learned all this in school, and I need to apply it. It doesn’t work out like that. I’m in the business of IT, not the technical aspects of IT. We outsource a lot of our technical work to a contractor, so I came in thinking I’m going to be doing HTML coding, and come to find out, no no no, I’m going to be providing oversight and management, getting scopes of work in place. Like Joey, I began to see all these business functions – we cover everything from soup to nuts. OHU, Legal, Environment, Operations, Maintenance, supply chain – all these business functions that support what we do as an organization. It’s pretty unusual for a company our size to cover such a wide breadth and span of responsibilities.

What was your familiarity with TAPS and Alaska?

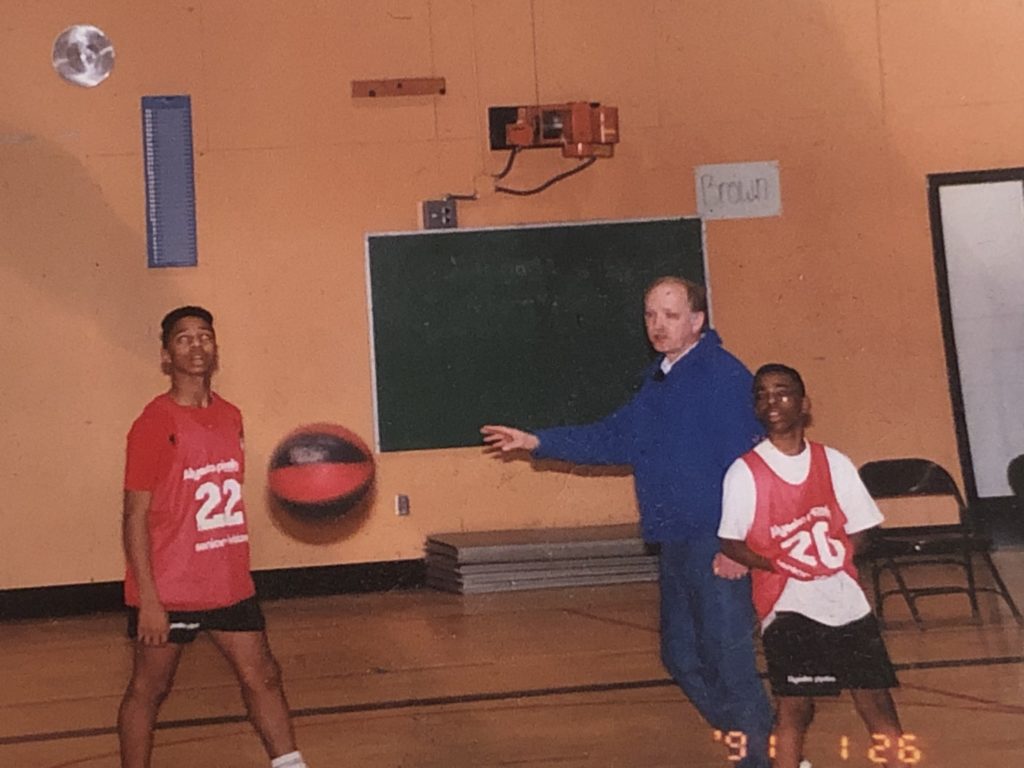

Joseph: I was born and raised here and only left for college. I found this old picture, probably back in 1988, ‘89, I forgot all about this, but Alyeska had sponsored one of our spring basketball teams, so I had a jersey on me at like age 12, playing for Alyeska pipeline back then.

Joey: I kind of married into TAPS. I was born and raised in Colorado, and I met my wife in school there. Over the summers, we would return to her home in Alaska to work. By the time we graduated, my mother-in-law, father-in-law and wife all had jobs on TAPS in Valdez. As far as my knowledge of Alaska and TAPS prior to meeting my wife; I knew Alaska was a big state, and I knew it had some oil in it; that was about it!

You were both hired around the same time; what are your impressions of the other’s team at Alyeska?

Joey: We rely on Joseph’s team day in and day out. They’ve helped us come up with new technology to answer whatever question happens to be facing us in a given day. That includes SharePoint sites, our electronic logbook software, our new scheduling software… Joseph’s team, is responsible for identifying where the cutting edge is, and then leveraging that technology to meet the business needs of the day. And as Joseph could probably point out, those needs change every day. We would come to a grinding halt without their help. So I’m grateful, especially to Satonya (Jumps) and Brian (McGurgan) who’ve spent so much time helping us recently. Joseph’s team is one of the many that makes it possible to even begin my day!

Joseph: The thing I would say about Joey’s team is I appreciate the hyper focus they need to do their jobs day in and day out. Twelve hours a day behind a desk looking at a screen, I don’t know how they do it all day but however they do it, they do it well. Not only are they monitoring, they’re also managing technology on the back end. In addition to reporting – because if anything goes awry, they’re on the hook to be the first responders, the first notifiers. It’s something I find amazing. We’re always looking for anything we can do to help them perform their jobs easier and make things go better.

Joey: I really appreciate that, I’m grateful for it. The things we take for granted are the things Joseph’s team make look easy. There’s so much work going on behind the curtain.

Today you are both in manager roles over teams that are so important to TAPS operations and reliability. Tell me about your approach to the job and the work.

Joey: I think anytime you are in a leadership position, your directive is straightforward, leadership is all about service. I’m sure Joseph feels the same way. My job is to serve the controllers and the control room. My job is to provision them with what they need to do their job, to protect them by keeping the unnecessary off their plate, to encourage them, and to empower them to take on that extra responsibility that comes from controlling an ever-evolving system. You talk in IT about being the defender of TAPS, and one of our cornerstones at OCC is taking ownership. What we mean is, it’s ok to respectfully and professionally step up and protect your pipe. It’s ok to be a little bit possessive when it comes to the Trans Alaska Pipeline System. It’s our job to make sure oil is safely and reliably delivered in a cost effective and environmentally responsible way. We’re focused on that core mission day in and day out, along with all our friends, system wide.

Joseph: Our role is overall a supportive role. The way we always look at ourselves is, what could we do not to just improve IT, but to improve the technology and the business uses of technology and data? Traditionally people looked at IT as information technology but it’s information and technology. At the end of the day we want to use this technology to drive business value.

What’s the most important work for your teams right now?

Joseph: We’re working two big strategies. One is reducing the amount of technical debt we have. Technical debt is when you go years without maintaining a particular technology. The longer you go, the harder it is, the more time intensive it is to maintain or upgrade that technology. When it comes to stability, the likelihood of an unplanned disruption also increases. So we’re looking at reducing technical debt in a way that our cost profile doesn’t go up significantly. The other thing we’re also focusing on is TSA mandates. Cyber has been identifying the remediation work and our resources do the planning and execution work to get us in compliance in support of these directives.

Joey: At the OCC, we emerged from cold weather operations at the end of April and rolled right into the shutdown and major maintenance season. We have six scheduled maintenance shutdowns this summer. Lately, you can feel it, as we get more daylight, the temperature starts to go up, the amount of work on our pipe just increases exponentially, and along with it, our focus becomes those shutdowns and supporting the teams in the field doing awesome work. Part of the reason this pipeline continues to thrive despite being around 45 years old, is that we pay so much attention to its maintenance and upkeep. So even though we’re busier now, we celebrate the work because we know it’s this work that will keep TAPS viable for the next 40 years.

Both of you have been on TAPS for nearly 20 years; what are the biggest changes you’ve seen in that time in your respective fields?

Joey: It’s really this evolution of smart technology. When I first started, a transmitter told you the pressure. An actuator closed and opened a valve. Now we have smart transmitters and smart actuators and a plethora of diagnostic information. The amount of data in the system has increased several orders of magnitude. It presents a real challenge, there’s a wealth of information, but you don’t want to throw all that information at a controller. It’s too much to deal with all at once. So what we’ve really worked hard on over the years is identifying, what is the critical information a controller needs to do their job safely? Then we have all this additional information, and we have to decide who receives that data, and what can we glean from it to help TAPS moving forward?

Joseph: You’re spot on when you’re talking about systems, Joey. That’s been the biggest advancement. Two big changes are when we went from analog to digital. Everything is digitized now. The other big change is the cloud. When the cloud hit – back in 2010, 2011 – we were all saying, ‘This is going to be a game changer,’ and it has been. We’ve been leveraging cloud-related technologies probably since I started.

And what in your respective field has stayed the same?

Joseph: What hasn’t changed is keeping things secure. We’ve got a heightened sensitivity toward it now, but keeping things secure, and keeping things reliable and stable. We’re always trying to find ways to make our systems run with the highest reliability that we can have. We’re also focused on extracting more business value out of these technologies, because if we aren’t getting the value or benefit, there’s no need to keep investing in it.

Joey: Yes, safety has always been at the forefront and that hasn’t changed. And more granular, under the banner of safety, personnel safety remains the trump card. I’ve worked around a lot of expensive and vulnerable process equipment, and at no point in my Alyeska career did I feel like the company valued that equipment more than me.

Joseph: Good point Joey. For us, security and safety go hand and hand. We’re not physically out in the field touching the equipment, but we look at data security, and systems security, that’s equivalent for us to safety.

What keeps you at Alyeska?

Joey: It’s absolutely the people. I call the OCC the clubhouse for nerds, I love it here. We work hard to maintain that culture. When we’re hiring new people, we’ll go through all their accomplishments and qualifications, but I make myself and the supervisors stop and say, “Okay, it’s the middle of the night and the line’s gone down, you’re in the ditch, up to your knees in mud. Which candidate do you want to see holding the shovel next to you?” By intentionally focusing on building the right culture, over the course of years, I think we’ve built a great team, where everyone has each other’s back. When it comes down to it, my job is just me and my friends getting to have a direct impact on the health and wellbeing of our state, and I wouldn’t trade that for anything.

Joseph: You stole my thunder, Joey. I’d say the exact same thing. What comes to mind is the people and the relationships. I consider myself a lifer here. Yes, I could go to other companies but would I want to? Absolutely not. The grass is not always greener. The culture here is so much different and better. There is a reason a lot of people have stayed for their entire careers here.

If you could go back to when you were hired and give your 2004 self some advice, what would you tell him?

Joey: 2004 Joey was pretty ridiculous. When you’re young, you’re very concerned with, “Am I getting enough credit, compensation, respect? Am I on the right career path?” I would tell 2004 Joey to forget all that and just focus on relationships. Let your career arc take care of itself and focus on building your teammates up and building allies across the company. I’m sure Joseph feels the same – a lot of the people I made friends with 20 years ago when we were all individual contributors and contractors, a lot of those people are still around, and in positions of influence. What’s allowed me to stay afloat is that I am not alone, I can leverage this network of amazing friendships forged over decades spent working together to keep oil flowing.

Joseph: Similar to what Joey said, I would tell myself, don’t worry about getting credit. I didn’t want to be seen as somebody who wasn’t delivering value, so to speak. And I would say, get as much exposure as I possibly can to the various areas within the business. Go out and meet with folks as a starting point.

READ MORE 45TH ANNIVERSARY REFLECTIONS FEATURES:

1979: A historic year for TAPS (video)

1985: The story of the ARCO Juneau (video)