1988: TAPS tops 2 million barrels a day

(This story was written and published in 2022 as part of the content created for the 45th anniversary of TAPS operations. Some of the sources in this story have changed roles at Alyeska or are retired and no longer with company.)

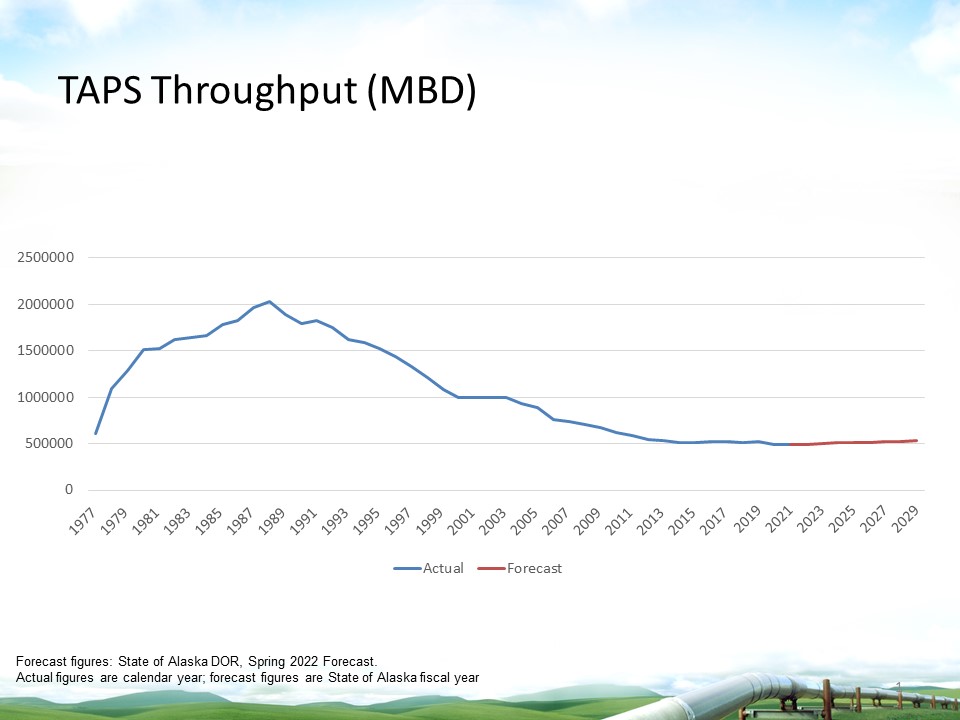

One commonly cited TAPS technical tidbit is that the pipeline was engineered for a mechanical capacity of 2 million barrels of oil per day in throughput. Yet in 1988, TAPS averaged 2,032,928 barrels per day and hit the all-time single-day high of 2,145,297 barrels on January 14.

How was that possible? Hundreds of extremely hardworking pipeline people across Alaska, every piece of TAPS infrastructure pushed to its max, and steady streams of drag-reducing agents (DRA).

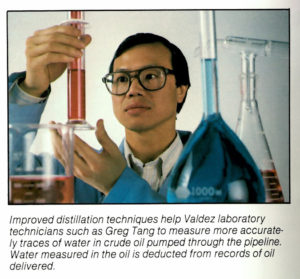

“Injection of drag-reducing agent into the pipeline played a major factor,” said Greg Tang, a Sr. Laboratory Technician at the Valdez Marine Terminal Analytical Lab during that time, “but it was the teamwork from all the employees to keep things running seamlessly.”

In 1988, Alaska accounted for 25 percent of the U.S. domestic production, though the price of a barrel of Alaska North Slope Crude Oil hovered around a meager $16 a barrel. With low prices pressuring the bottom line for TAPS Owners and Alyeska leaders, pipeline operations were pumped up to new levels of volume. And all 28 of TAPS’ mainline units were rocking: three each at PS1, PS3, PS4, PS6, PS8, PS9, PS10 and PS12; two each at PS2 and PS7.

The throughput spike was a very big deal for oil producers, Alaska and America. But on TAPS, fast-paced, high-throughput work was now the norm. While few workers say they don’t recall January 14 as a special day at the time, all, however, remember the camaraderie that kept TAPS operating above-and-beyond expectations though that 1988.

The 2 million barrels annual average was never reached again. In fact, only 14 months in 45 years of TAPS operations had a throughput average that exceeded 2 million barrels; 11 of those months were in 1988. 1987 came close at 1,963,770, and is the only other year averaging above 1.9 million. By 1989, TAPS averaged 1,884,829 barrels per day and hasn’t averaged more than 1 million barrels daily since 2002 (1,000,916).

What was it like moving 2 million barrels a day? Here are some perspectives from pipeline people who were there (and a few who came shortly after), most of whom still work on TAPS.

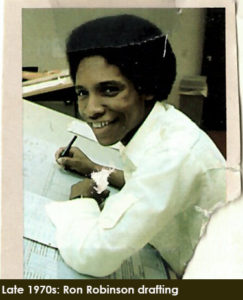

Ron Robinson, retired, formerly Drawing SME/Site Engineering, 1982 Alyeska hire, worked in Anchorage as Electrical Designer and Sr. Electrical Designer during that era: “Pride was at an all-time high for TAPS workers/Alyeska. Certainly, the State of Alaska and the energy industry were pleased to see throughput reach that level. I don’t think Alaska residents were aware of the accomplishment. On a national level, some people thought the pipeline was still under construction.”

Ron Robinson, retired, formerly Drawing SME/Site Engineering, 1982 Alyeska hire, worked in Anchorage as Electrical Designer and Sr. Electrical Designer during that era: “Pride was at an all-time high for TAPS workers/Alyeska. Certainly, the State of Alaska and the energy industry were pleased to see throughput reach that level. I don’t think Alaska residents were aware of the accomplishment. On a national level, some people thought the pipeline was still under construction.”

Scott “Chip” Conroy, currently OCC Lead Controller, 1979 Alyeska hire, worked in the Bragaw headquarters in the General Services department and Alyeska Distribution Center during that era: “I was in non-operations-oriented positions, but I knew something special was going on. The Bragaw offices were buzzing. While working at the warehouse, I definitely saw the impact the higher throughput had on Alyeska. The amount of freight and goods going to the pump stations and Valdez was astounding.”

Mark Dahl, currently Maintenance Supervisor/Maintenance North, 1986 Alyeska hire, worked as Operations Technician in Power Vapor/Oil Movement & Storage group at the Valdez Marine Terminal during that era: “The energy around TAPS workers in Valdez was high, but also family-like … one of excitement and great pride in our accomplishments.”

Mel Jessee, currently Acting General Audit Manager, 1975 Alyeska hire, worked as the Financial Planning Coordinator during that era: “Several compounding factors contributed to a very challenging business environment during that time. The low cost per barrel of crude challenged our annual budgets and LRP forecasts. Alyeska budgets were under significant pressure to reduce costs. I specifically remember the 1988 LRP including Alyeska headcount reductions with a projected target of 600 employees. Small profit margins per barrel for TAPS shippers was offset by the increased volume of barrels by maximizing throughput capacity.”

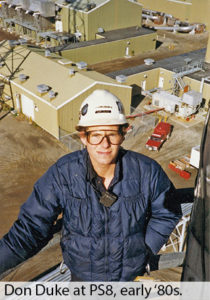

Don Duke II, Alyeska hire 1976, currently Shops Maintenance/North Pole Metering Technician, worked as technician at Pump Station 8 during that era: “The often overlooked and at times unspoken fact was that TAPS provided a very significant amount of our domestic oil. We all knew that and worked hard to meet the challenge.”

Pump stations and pipeline people: All systems go

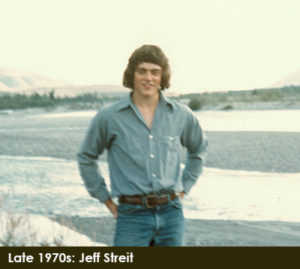

Jeff Streit, currently Response Base Supervisor at Glennallen Response Base, 1978 Alyeska hire, technician at Pump Station 1 during that era: “There were 62,571 gallons of oil per minute moving through this system, the equivalent of eight 8,000 gallon fuel tankers coming past you on the highway every minute or one every 7.5 seconds, 24 hours a day. … The real accomplishment was everything had to be online and working. … Some stations were burning up to 75,000 gallons of fuel every day for moving oil and power generation.”

Jeff Streit, currently Response Base Supervisor at Glennallen Response Base, 1978 Alyeska hire, technician at Pump Station 1 during that era: “There were 62,571 gallons of oil per minute moving through this system, the equivalent of eight 8,000 gallon fuel tankers coming past you on the highway every minute or one every 7.5 seconds, 24 hours a day. … The real accomplishment was everything had to be online and working. … Some stations were burning up to 75,000 gallons of fuel every day for moving oil and power generation.”

Mark Dahl: “We were challenged with operating the power plant at significant loads and the vapor recovery system at the limits of its capabilities without much automation. On the oil movement side, all four berth meter sets were in operation and as a metering operator, your shift was quite busy. On the Terminal, all 18 crude tanks were in service and were being routinely operated at higher levels than today. There was no real redundancy, particularly in power vapor and metering systems … an outage immediately impacted the ability to move enough oil across the Terminal without affecting throughput.”

Ron Robinson: “The engineering and construction of TAPS was remarkable. I don’t think anyone would have been surprised if 3 million barrels were transported. As long as Alyeska could receive every barrel delivered to us, there were no pressure or concerns. There was never excitement about throughput, especially in the Corporate office staff unless there was an upset.”

Scott “Chip” Conroy: “After I transferred to PS1 in 1993, I was exposed to some of the most amazing and talented individuals on TAPS. These technicians, engineers and support staff were key to operating TAPS to its upper limits. I was always amazed by the stories they told around the break table of those times where every piece of equipment on the pump station had to run to its max to meet throughput demands.”

Don Duke II: “Running all turbines that hard all the time burned a lot of fuel. Squeezing out as much fuel as we could from our small refinery – topping unit – was not only a great challenge, but essential to keeping the turbines running up and down the pipeline. At PS8 alone, each unit burned approx. 25k gallons a day. That was 75k a day just for PS8! … (Did I feel pressure?) Very much so. PS8 ran on discharge control during this time which was 1060 psig (pounds per square in gauge). If we were 1 psig under that our supervisor would get a call wanting to know why and how soon would we be back to 1060 psig. It was hard to keep the old Westinghouse Veritrack instrumentation that tight.”

Don Duke II: “Running all turbines that hard all the time burned a lot of fuel. Squeezing out as much fuel as we could from our small refinery – topping unit – was not only a great challenge, but essential to keeping the turbines running up and down the pipeline. At PS8 alone, each unit burned approx. 25k gallons a day. That was 75k a day just for PS8! … (Did I feel pressure?) Very much so. PS8 ran on discharge control during this time which was 1060 psig (pounds per square in gauge). If we were 1 psig under that our supervisor would get a call wanting to know why and how soon would we be back to 1060 psig. It was hard to keep the old Westinghouse Veritrack instrumentation that tight.”

Greg Tang, currently a Field Science Technician at the Valdez Laboratory, 1977 Alyeska hire, worked as Sr. Laboratory Technician at the Valdez Marine Terminal Analytical Lab during that era: “I was measuring the quality of crude oil coming into the Terminal and loading on the tankers, and monitoring the water quality of treated ballast water discharged into the Valdez port to ensure it met the EPA discharge permit requirements. … The Terminal operated Berths 1, 3, 4 and 5. Many days there were four tankers at the berths simultaneously. Our record was five tanker departures in 24 hours, which also meant that the lab had five custody transfer crude oil samples for the vessels analyzed in one day.”

Mel Jessee: “The high volume of crude required 100 percent reliability at all TAPS facilities. TAPS operations required that all pump station mainline units (MLUs) remain running 24/7 and ‘Throughput was king.’ The Anchorage Maintenance Facility remained on-call 24/7 to respond to any mainline failure with specialized technicians and parts ready to fly out as soon as possible to get MLUs back online.”

2 million and beyond: DRA ASAP

Jeff Streit: “We had maxed out everything we could so the next step was to install more pumps and add more DRA. … DRA was being injected at multiple locations. It came into Fairbanks on railroad cars, each carrying 10,000 gallons.”

Mel Jessee: “From a financial perspective, short-term DRA operating costs were significantly less than the long-term costs of additional capital facility additions. Much of the original TAPS “Phase 3” facilities required to achieve 2 million barrels-plus per day mechanical capacity were never required due to DRA use. This included PS5, where MLUs were never added, PS11 that was never built and where GRB is today, and fourth MLUs were never added at other stations.”

Mel Jessee: “From a financial perspective, short-term DRA operating costs were significantly less than the long-term costs of additional capital facility additions. Much of the original TAPS “Phase 3” facilities required to achieve 2 million barrels-plus per day mechanical capacity were never required due to DRA use. This included PS5, where MLUs were never added, PS11 that was never built and where GRB is today, and fourth MLUs were never added at other stations.”

Mark Dahl: “On the pipeline, drag reducing agent was being injected continuously at PS4 and PS10.”

Don Duke II: “The introduction of DRA was somewhat responsible through those years, as well as multiple disciplines in the field and offices thinking outside the box.”

TAPS maintenance: NASCAR pitstops

Jeff Streit: “There were only eight hours per month for MLU maintenance. It was like a NASCAR pitstop to get everything done.”

Mark Dahl: “In order to perform scheduled MLU maintenance, there were quarterly maintenance days wherein either even or odd numbered stations could bring down one MLU at a time. OCC would start the maintenance day with PS1 tankage at minimum and struggle to end the day with room left (in the tank).”

Joel Lindsey, currently Implementation Assurance Lead/Campaign Maintenance, 1978 Alyeska hire, was an Area Team Leader at PS5, 7 and 8 during that era: “It took three months to get work done on all three MLUs. We would get our PMs assigned and any repair work orders ready. The permit would be written by the night shift and after a review of the work for the day, we got to it. The unit had to be back online by 6 p.m.”

Don Duke II: “Oh, and by the way, no such thing as a 15-hour work rule. It was all hands on deck until all was complete. Sometimes into the second day.”

2,145,297 barrels on January 14: A day to remember?

Greg Tang: “We did not even know that we hit a record. Two-plus million barrels per day was just a normal day of work.”

Greg Tang: “We did not even know that we hit a record. Two-plus million barrels per day was just a normal day of work.”

Jeff Streit: “We didn’t know it was a peak at the time, because we ran close to this number throughout a year, not just one day.”

Joel Lindsey: “The producers just kept bringing on more oil and we kept moving it south to VMT and kept the stations pumping oil. … In the field, we knew we were moving a lot of oil, but the volume was not something we noticed.”

Ron Robinson: “I don’t remember anything specific about that day. In hindsight, no one knew how special the peak was until throughput began declining.”

All downhill? Throughput drops, #TAPSPride remains high

Joel Lindsey: “When I got a job with Alyeska in 1978, I quit looking – this was the best job you could get and still is. Keep the oil moving then and now is the job – everything we all do contributes to that task, whether the person realizes it or not.”

Joel Lindsey: “When I got a job with Alyeska in 1978, I quit looking – this was the best job you could get and still is. Keep the oil moving then and now is the job – everything we all do contributes to that task, whether the person realizes it or not.”

Scott “Chip” Conroy: “Now that I have been in operations pushing 30 years and working OCC, I see the real significance of what that was. I think about now at 500,000 and what it would be like as an OCC Controller to load four times the amount of tankers that we currently do or have so many pump stations operating puts it in perspective for me.”

Mel Jessee: “There were extreme highs and lows during the 1988-1989 era. The record high throughput levels followed by the low gut punch of the Exxon Valdez oil spill. … Overall, (Alyeska) didn’t control throughput, we just worked hard to keep up with the increased volume forecasts from the producers and they were maximizing their production capacity in order to remain profitable. There were many things that had to be managed well to support the high throughput years on TAPS. Credit goes out to our brilliant engineers and hardworking operations and maintenance personnel who made it all possible.”

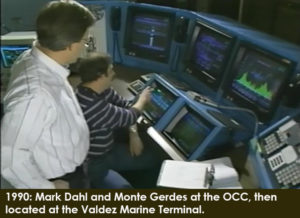

Mike Malvick, Alyeska hire in 1991, currently Sr. Process Engineer: “Shortly after I was hired, I went to the Operations Control Center, which was still at the Valdez Marine Terminal. OCC kept a board with all sorts of records – most barrels of oil pumped in a day, most tankers loaded in a month, etc. One of the controllers there, maybe John Martin, and I were talking about the day’s throughput and it was about 1.6M or 1.7M barrels per day. He said, ‘We’ll never see that 2.1MM number again,’ and pointed at the record board. That should have been a clue about what was coming, and 30 years later I’m still here, learning how to operate a pipeline at 25 percent of design capacity.”

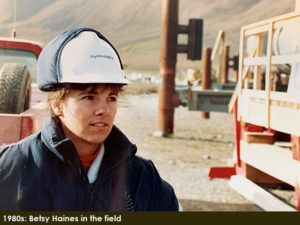

Betsy Haines, Alyeska hire in 1990 in Projects and rose to Operations Vice President, now Interim President: “When I started, there was never a discussion about the primary business of the pipeline. I had no idea about the amount of oil going through. But I do have this memory: in the manifold buildings, the pipe was warm. It was always so nice to go in there because it was so warm. … The first job I had was at Pump 4 and we shut the line down to take out piping. It was a 12-hour shutdown, and being shut down was a big, big, big deal. We were the one station that had gone over the time. Every minute, I swear, we were getting calls – When are you going to come up? When are you going to come up? I thought, ‘What is wrong with you people?’ But in hindsight I get it. All of those things were just dialed in because we didn’t want to impact flow. … The other thing about that time was so many pump stations were operating – it just made you feel like this is a big system. Man, what a huge system. I remember that, and all the equipment needed to move the oil.”

Betsy Haines, Alyeska hire in 1990 in Projects and rose to Operations Vice President, now Interim President: “When I started, there was never a discussion about the primary business of the pipeline. I had no idea about the amount of oil going through. But I do have this memory: in the manifold buildings, the pipe was warm. It was always so nice to go in there because it was so warm. … The first job I had was at Pump 4 and we shut the line down to take out piping. It was a 12-hour shutdown, and being shut down was a big, big, big deal. We were the one station that had gone over the time. Every minute, I swear, we were getting calls – When are you going to come up? When are you going to come up? I thought, ‘What is wrong with you people?’ But in hindsight I get it. All of those things were just dialed in because we didn’t want to impact flow. … The other thing about that time was so many pump stations were operating – it just made you feel like this is a big system. Man, what a huge system. I remember that, and all the equipment needed to move the oil.”

READ MORE 45TH ANNIVERSARY IMAGINATION & INGENUITY STORIES:

1984: TAPS Telecoms Then & Now with Dana Orr

1992: New otter, bird facilities support rescue, care

2001: Wild Ideas: What if TAPS was topped by a bridge, boat or plane?