1984: TAPS Telecoms Then & Now, with Dana Orr

“As I think about my history, I feel like an old-timer. I can’t say I have felt that way in this job, though, as it’s always providing new and better technologies and solutions.”

Think cell phone technology has evolved in recent years? Ask Dana Orr about the often-revolutionary stages of TAPS telecommunications over the past 45-plus years. Dana has worked on TAPS since 1994: for 10 years as an Alyeska Telecom Specialist contractor, and since as Alyeska’s Enterprise Telecom Lead. She wasn’t around for every TAPS telecom installation and innovation, breakthrough and breakdown. But she’s practically improved or removed most of them and introduced dozens more.

“When I came to work on TAPS, there were no cell phones, there was no internet to the pump stations, only a small enterprise data network between Anchorage, Valdez, Fairbanks and the pump stations with very limited ability to make voice calls to other locations,” Dana said. “Control of the pipeline consumed 1.54 Mbps (equivalent to a single TEAMS session with video) while total bandwidth supporting all TAPS operations was no more than 24 Mbps end-to-end on the pipe. ARTS (1) radio system was the only voice communications option for field operations. Alyeska Cyber Security thoughts were in their infancy.”

Telecoms on TAPS has certainly grown up fast. Dana’s work focuses on making communication as dependable, secure, simplified and as fast as possible for workers at TAPS locations across the state, and for those supporting the communications systems with safe and reliable TAPS operations in mind. That’s meant one complex project after another, each with the potential to create communication where it’s difficult or once wasn’t even possible. She’s also an industry leader beyond TAPS, holding Vice Chair of the American Petroleum Industry Telecommunications Board to the FCC from 2017-2020.

Telecoms on TAPS has certainly grown up fast. Dana’s work focuses on making communication as dependable, secure, simplified and as fast as possible for workers at TAPS locations across the state, and for those supporting the communications systems with safe and reliable TAPS operations in mind. That’s meant one complex project after another, each with the potential to create communication where it’s difficult or once wasn’t even possible. She’s also an industry leader beyond TAPS, holding Vice Chair of the American Petroleum Industry Telecommunications Board to the FCC from 2017-2020.

“As I think about my history, I feel like an old-timer,” Dana joked. “I can’t say I have felt that way in this job, though, as it’s always providing new and better technologies and solutions. In Telecom, this is probably the one job that when I do it right no one thinks about me or knows I am here. But when it goes wrong, it gets a lot of attention.”

What’s changed about TAPS telecoms since startup? What’s the future hold? We made the call and Dana answered.

You’ve worked on TAPS for nearly 30 years. What’s kept you around so long?

Dana: Two things: the people I get to work with and the diversity of work that I get to do. The constant change in technology makes it a continuous learning event. I don’t get bored. I have had a lot of touch points on many projects, and it has given me a wonderful opportunity to get to know the broad scope of Alyeska operations and the amazing people that deliver the work across the organization.

What are the challenges of providing reliable telecommunications along the TAPS route, to office locations across Alaska, and so many points in-between?

Dana: The most challenging part of Alyeska’s communications is also the most intriguing part for me: the infrastructure is not in place and must be built out. That’s a fun challenge, collaborating for a design and implementation of services and seeing them completed. Because Alyeska is the main customer of telecommunication services along the pipeline, it is not an off-the-shelf type of commodity you would find in urban areas. Instead, to add services I must create internal support, potentially add new contracts, and determine the technology and then implement the build out the services.

TAPS communications isn’t just telecoms anymore. It’s internet, Wi-Fi and cellular service, live video, cyber, and physical security technology. Alyeska’s workplaces are so unique, too. How do you “even the playing field” and provide the same – or as close as possible – services for everyone?

Dana: You are right, most everything plugs into a network for remote access, or is a service delivered via internet connection. It is hard to even the playing field of bandwidth as many programs will consume as much bandwidth as they are allowed. This drives us to make decisions based on our prime reason to operate – simply put, “We move oil.” To move oil, at a very minimum we need our controls systems, therefore these systems have services that are designed so they are not competing with other technologies and these networks can operate in resilient, highly available fashion.

From there, the remainder of available bandwidth is allocated. The largest bandwidth consumer is enterprise services such as email, security video and Microsoft Teams. In recent years, Alyeska partnered with GCI to upgrade service delivery hardware components along the pipeline, enabling the provision of more bandwidth for consumption. We’re constantly restructuring networks as more bandwidth and service delivery options become available, enhancing delivery, reliability, and user experience.

What have you heard about TAPS telecoms in the ’70s and ‘80s and how has it evolved?

Dana: One of the large differences is where the workers are located. Until the mid-‘90s, there were more permanent workers at pump stations for operational support. They needed to communicate among themselves and access local computer resources, which didn’t require much bandwidth between locations. When AT&T’s bandwidth contract was implemented in 2005, workers were still onsite and it was stated that, “Control would never require more than 10 T1s to operate the pipeline for all alarming, safety systems and control” or a total of 15 Mbps. Most people have more bandwidth to their house now than we used for operations and control of the pipeline!

When Alyeska removed people from the field, it flip-flopped support needs. People now work from urban offices or home, and we now have a cloud-first strategy for most IT services. This change meant that pump station networks, to include internet access, needed to expand to all areas of the pipeline, creating an 800-mile office.

What was TAPS telecom infrastructure like when you started in the ‘90s? What were the exciting projects and big hurdles you faced?

Dana: Communication projects take many years to come to fruition as a whole, but TAPS is even more complicated due to being in very rural areas of Alaska, this was again present when Alyeska had to envision and build the next iteration of communications after start-up. In 1994 there was the realization that new communications infrastructure was needed to provide the desired remote alarming and control capabilities, networks to connect these devices, and the ability to connect to the internet from all Alyeska locations. A design and implementation plan for a new fiber system from PS 1 to Valdez was created. I was added to the team to provide circuit engineering and provisioning. As a result of these efforts, there was a communication system that ran the length of the pipeline and to the RGVs carrying TAPS controls, voice, and data communication. This build-out, like the original installation of the pipeline, had many challenges. Installing fiber in the Arctic environment was new, as were the best practices. Many of these practices were being developed as the project progressed.

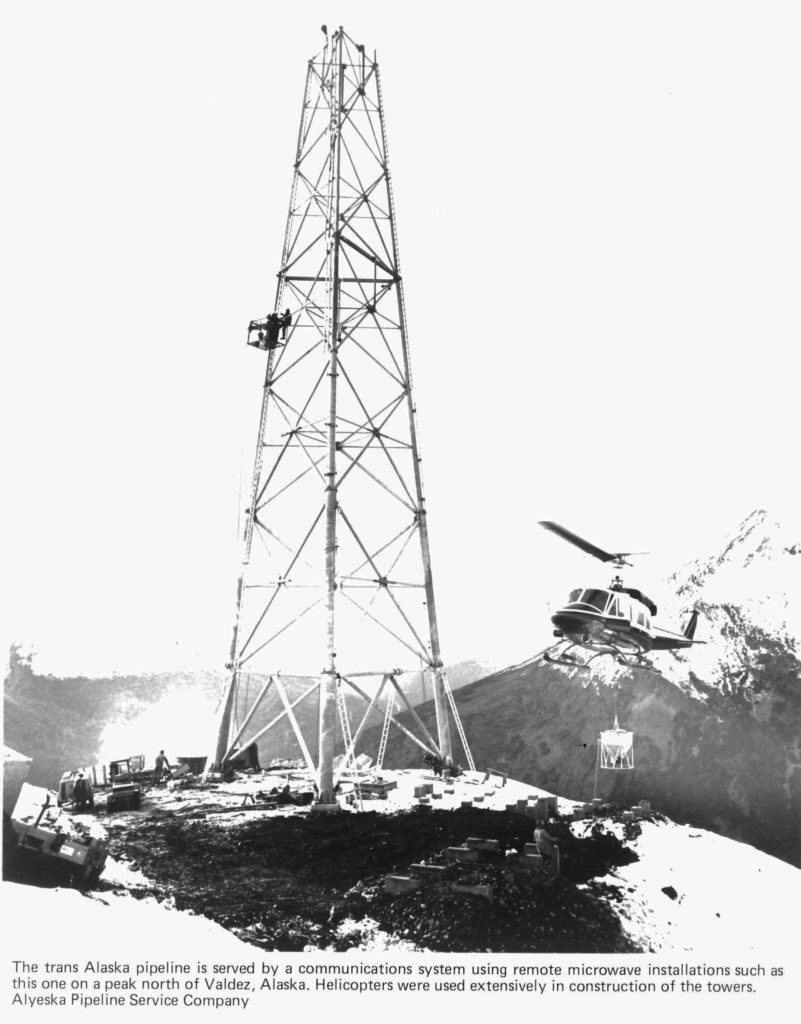

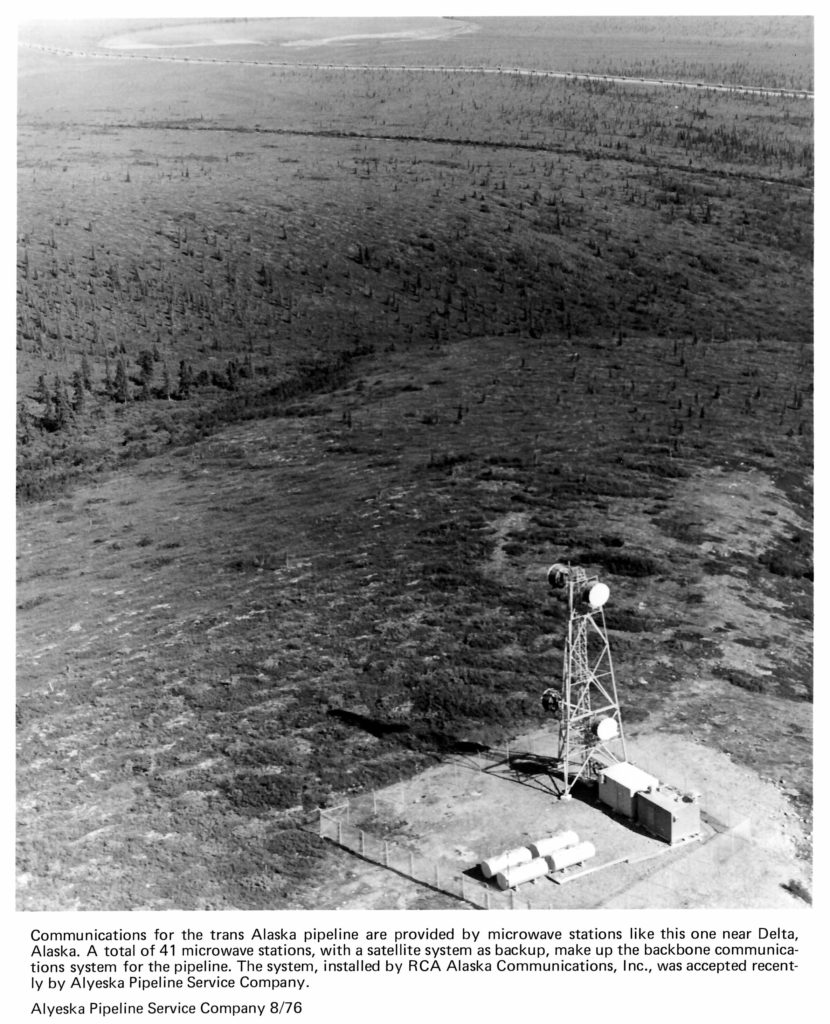

During the winter of 1997 two concurrent fiber incidents isolated the pipeline data to individual segments of the pipeline causing OCC to lose visibility and then initiated a shutdown. It was this incident that made everyone realize that more resiliency through geographically diverse communication paths needed to be designed and implemented to ensure reliable operations. To obtain this level of reliability, Alyeska engaged AT&T to add the original communication route of the microwaves on mountaintop repeater sites, to the overall system delivery. This was wrapped up into a comprehensive long-term contract for bandwidth with AT&T. It enabled engineering to start implementing the desired remote data and pipeline control technologies.

This was Alyeska’s first round of transformation with technology. It was an exciting time, and I was lucky to be a part of the team that implemented the first transformation.

Tell us about ARTS. It was and remains a game-changer, right?

Tell us about ARTS. It was and remains a game-changer, right?

Dana: Alyeska Radio Telephone System (ARTS) was built in parallel with the pipeline. It was before my time, but yes, it is a game-changer to have communications where no other methods of communications exist. It provides a communication safety-net for field workers and allows for day-to-day operational communications along the right of way and at pump stations. A little-known fact is that Alyeska had to have this ARTS communication system operational prior to starting the pipeline and it continues to be a method of compliance as part of our federal regulations requirements in “conducting two-way vocal communication between a control center and the scene of abnormal operations and emergencies.”

Now, about the present and future of TAPS comms. Pump stations have Wi-Fi. There are more, stronger cell coverage areas. And you just wrapped a significant project to improve bandwidth on the TAPS right of way. Tell us more.

Dana: It has been a wild ride for upgrading and creating communications systems for TAPS in recent years, and I only expect it to get faster as technology changes. The communication infrastructure is aging and doesn’t support the modern bandwidth needs. Hardware upgrades must be implemented to continue to facilitate Alyeska’s operations in a remote data-driven environment.

In 2018, we upgraded the GCI hardware components on the RGV system and concurrently created a partnership with GCI to provide the first cell services between Coldfoot and PS1, and at PS4. Then, in 2020, we worked with GCI to upgrade their hardware components at PS1, 2, 3, 4, 5, 6, 7 and NPMS. At the same time, I created a strategic partnership with Arctic Slope Telephone Assn. Cooperative to build and install three comm huts to support AT&T cell services at PS2, 3 and 4. Both projects went live December 2020.

In addition, I helped implement new remote worker infrastructure. That was a crazy COVID year. The services all ran concurrently, so while many people slowed down during COVID, I had to, as did others, speed up to implement these transformations. The satisfaction came from working with so many amazing people to bring this effort to fruition for Alyeska, the North Slope and Alaska in general. This new infrastructure immediately delivered cellular technology for Alyeska operations and laid the foundation to build more telecommunications projects in the future. Just recalling this effort makes me grin from ear to ear.

Recently we finished this GCI hardware effort over 2021-2022 for the southern system – DIF, NPMS, PS8, 9, 10, 11, 12, VMT and Petro Star. This was completed in April 2022. SERVS to VMT had dark fiber installed and services cut over.

With your work, you’ve been to pretty much all TAPS locations. Do you have any favorite memories?

With your work, you’ve been to pretty much all TAPS locations. Do you have any favorite memories?

Dana: I get to see some very cool scenery, from mountaintop repeater sites along the pipeline, to communication sites in Prince William Sound, to the operations at the pump stations. TAPS is so mutable in all aspects; I see it differently every time. What I always reflect back to is the grit and ingenuity of the folks that built all of this and continue to operate and maintain it. All of this in these extreme, but beautiful locations, it just makes me say ‘Wow!’

READ MORE 45TH ANNIVERSARY IMAGINATION & INGENUITY STORIES:

1988: Throughput peak: TAPS tops 2 million barrels a day

1992: New otter, bird facilities support rescue, care

2001: Wild Ideas: What if TAPS was topped by a bridge, boat or plane?